Products

High-quality equipment plays a vital role in overall product quality.

Machine manufacturers can tailor production systems down to the last detail to ensure the quality of the manufactured product.

We manufacture the following products.

Laminar Air Flow

Laminar air flow systems are used in various applications such as life science research, microbiology, IVF, pathology lab, plant tissue and cell culture and pharmaceutical and electronics industry and many more. These stations are built with respect to the type of process being performed.

There are times when maintaining a very high level of cleanliness is desired, so a laminar air flow cabinet or bench may reside inside an existing cleanroom. Other times, a cabinet may be a standalone design in a facility without a cleanroom at all.

Laminar Flow Cabinets are typically designed to protect the working area only. They do not offer operator protection and are not suitable for working with biohazards.It maintains cleanliness Grade A / Class 100 underneath of HEPA filtration in the chamber

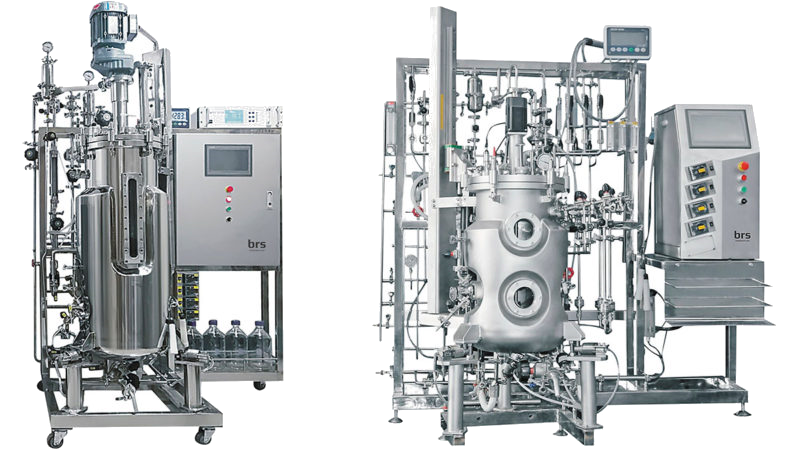

Manufacturing Tank/Bioreactors/Fermenters

Verities of the stainless-steel jacketed tank ranging from 25 Ltr to 10000 Ltr, widely applicable in Pharma / Biotech / FMCG / API Industries for Manufacturing & Bioreactions.

Clean room Light Fixtures

Hygienic, efficient and cost-effective solutions with excellent vision at workplaces in Operational area.

Pharmaglance provides various solutions for flooring according to specific requirements of the project.

HEPA Filter with LED.

Patented Clean room technology with combi solution of HEPA filter and Light fixtures in common Terminal, Reduces Cleanroom cost with the same footprint.

Isolators

Isolators are typically equipped with a fully reproducible and validated system for bio decontamination (mostly H2O2) and a process air handling unit (AHU) that ensures temperature control by heating or cooling, as well as permanent overpressure/ Negative control of the process area compared to the operator environment in the clean room.

An aseptic isolator protects the product from contaminants in the environment.

Positive pressure is maintained in the isolator in order to ensure that particles from the setup room will not enter the isolator and contaminate the product in the case of even a very minimal leak.

Purified Water System / Pure Steam Generator

Water technology which fulfils your requirement & comply USP and other Regulatory for Pharmaceutical / Biotech / FMCG / API Use.

Pre-treatment – Purification with Distribution – Water for Injections Generation & Distribution – Pure steam Generation & Distribution.

Racking

Storage facilities are a crucial component of using cost and time effectively.

These systems need to comply with Good Manufacturing Practices for safe keeping of inventory in pharmaceutical industries.

These are designed according to the requirements of the clients and products that are to be kept in these systems.

Pass box

Material transfer equipment plays an important role in minimizing contamination risks during the manufacturing process.

Non-viable particles and microorganisms can cause contamination in a cleanroom due to this entry and exit of materials within the controlled environments. we have adopted the principles given in ISO 14644 and other standards for making Pass boxes.

Again we believe to deliver this solution cost effective and maintenance free.